So basically I'm going to focus on 2 systems the slab system and the block system.

- Slab system

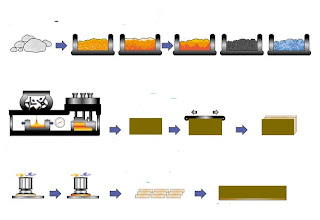

The loading of the grain sized natural quartz, silica sand or other raw materials into the mixer is followed by quartz powder, polyester resin and colouring pigments.

The mixer is then transported in conveyor belts and spread on the slab mould, due to the low thickness of the slab (maximum 3 cm) it's not necessary to mix in vaccum like the block system. Next it goes into a vacuum and vibrocompression chamber,much less powerful than the one in the block system, as it only has to compress a slab at a time. After this stage the slab will follow a conveyor into a oven, this will accelerate the cure making it usable in a few hours ... I guess we can say that it's a continuous production line.

Next we have the calibrating and polishing lines. Note that these slabs will be calibrated on both sides before polishing to insure that it is correctly calibrated. The polishing is made with granite type machinery, and are also difficult to polish especially the darker colours.

- Block system

So the raw natural materials are loaded to the mixer, where other products will be added like stone powder, polyester resin and colouring pigments. They have to be mixed thoroughly together and in vacuum to avoid air bubbles and bad mixture. Next the whole mixture is discharged into a big rectangle mould, this mould after being filled with the mixture will be compressed with a heavy duty compressing system. The whole floor of the factory will tremble during this process, just to have an idea of the power applied. After this phase the chemical reaction has attained a gel state, and in a few hours it will become solid. Although the slab production is continuous, the block needs a few days of curing.

After these few days in resting, the block may be sawn like any ordinary marble block. It has one special characteristic, it can be sawn in thickness as low as 9 mm, which in some marbles is rather difficult not to say impossible without any resin reinforcements.

The polishing line has an initial calibrating system, all top quality agglomerate stones have small thickness tolerances, so calibrating is an important part of the production cycle. Next is polishing, polishing is rather difficult on these products due to the resin in its composition, but most manufacturers have overcome this problem with the use of the proper abrasive line.

At this point you'll have a slab ready to ship or cut to size.

Some Q&A

Can you make marble based agglomerate on slab system?

Yes you can, however the commercial value of quartz is much higher, it's economically better to make quartz. And you'll need specific polishing equipment to polish marble based material.

Can agglomerates appear with pin holes on the surface?

Yes, this means the equipment has a undetected defect, the vacuum system is not working properly.

How many block systems are producing?

It was the original technology that began around the 80s, however in the last few years almost all systems installed have been slab type. However in China their has been several block systems activated in the last few years. In Europe, you can only find them in 3/4 countries. It's more or less basic that most block systems have difficulty in giving a good return on investment.

1 comments:

A very well-written post Marble Exporters , Marble Manufacturers , Marble Suppliers , Marble Tiles Manufacturers , Marble Slab Manufacturers , Marble Blocks Manufacturers

Post a Comment